Company

The Costruzioni Meccaniche Zanetti operates as a mechanical workshop in the steel and engineering industry since 1980.

Thanks to the will and constancy of Mr. Pierino Zanetti, the company has progressed over time constantly improving its know-how in a persistent improvement of the fleet.

Always attentive to technological upgrading and staff training, the Company has structured itself to best meet all the requirements relating to the construction, maintenance and repair of spare parts for the metalworking, iron and steel industries in Italy and abroad.

Our services

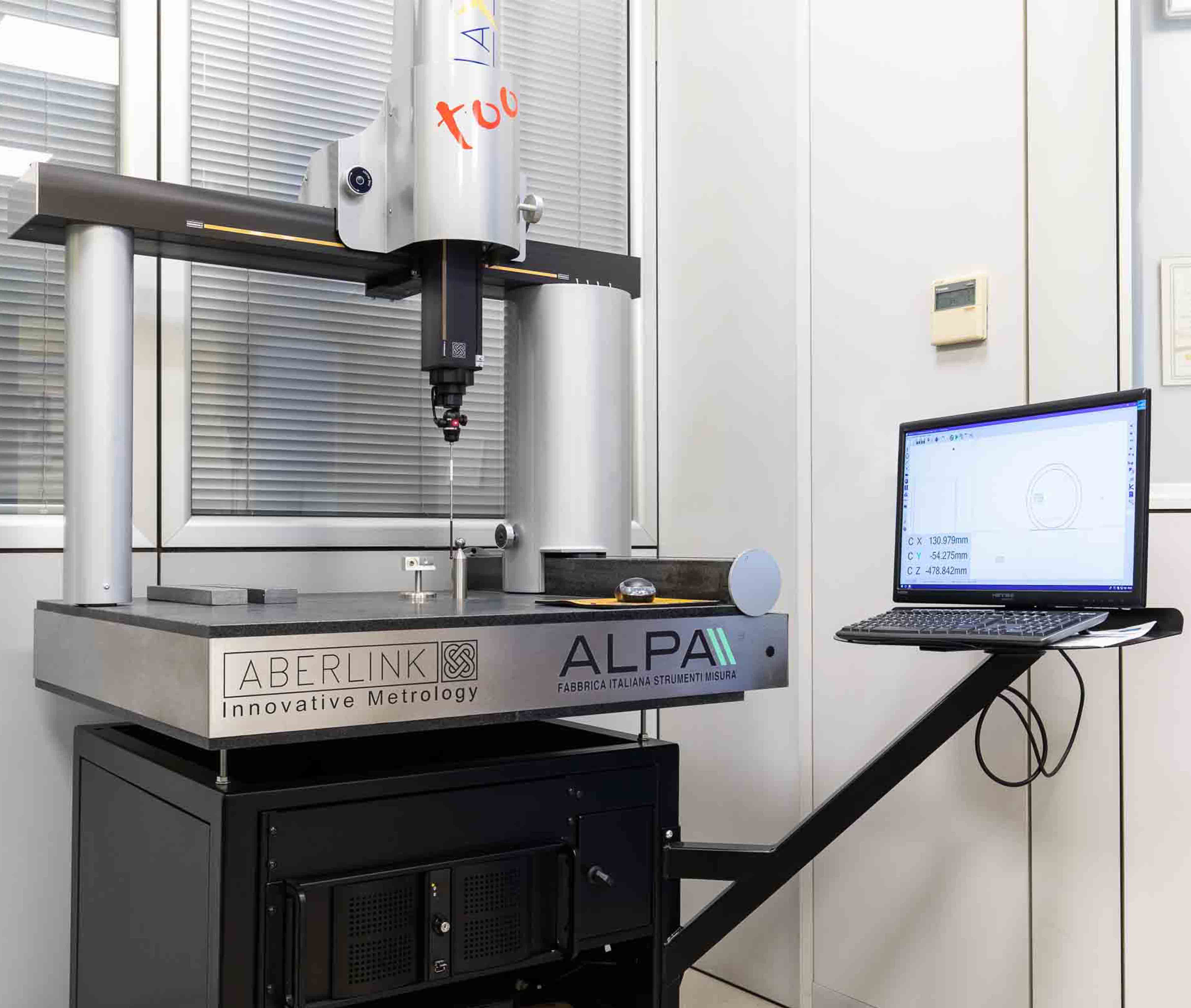

THREE-DIMENSIONAL MEASUREMENTS

The dimensional measurement team of Costruzioni Meccaniche Zanetti can support the various needs of customers by collaborating together in the different life phases of a component.

Our in-house technical laboratory , equipped with the latest generation technologies for three-dimensional measurement, guarantees very high precision and maximum reliability in measuring every detail of geometry complex, for the products or components of the various sectors of the mechanical and steel industry .

The three-dimensional measurement processes, performed exclusively in our laboratory, take place in an innovative metrological room at controlled temperature.

THE AIR-CONDITIONED METROLOGICAL HALL is equipped with the most advanced devices, tools and equipment for precision testing.

We perform the dimensional check service and testing of mechanical components also on the client’s advice, to assess the product’s compliance with the specifications of the construction drawing.

We have a complete range of measurement and control equipment.

We guarantee transport directly to the customer.

Processing

Several sectors are involved through the “ processing services ” that Costruzioni Meccaniche Zanetti manages to satisfy; Petrochemical, ecological, mechanical and mainly medium and large-sized industries in the steel industry sector.

FROM THE RAW TO THE FINISHED PIECE IN QUICK TIMES AND WITH QUALITY

The operating department, made up of competent and experienced people, is able to transform a piece from raw to finished in a short time, thanks to the numerical control machines such as lathes with a turning diameter up to 1000 mm and milling machines with a length up to 3000 mm.

Specifically, finished piece with:

Teeth![]()

![]() Broaching

Broaching

![]() Heat treatment on the material

Heat treatment on the material

![]() Adjustment

Adjustment

![]() Report in submerged arc

Report in submerged arc

Processes are carried out according to specific regulations and are associated with specific process sheets and control certifications; also we perform maintenance on steelmaking machinery.

SUBMERGED ARC WELDING

When it comes to tackling the daily challenges of junction welding, in protection from wear and corrosion, the welding technician team of Zanetti Mechanical Constructions, ready to best meet the requirements of our customers and partners.

Guaranteed results of submerged arc welding up to a diameter of 1000mm.

SMALL CARPENTRY

Carpentry workings mechanics light.

We operate on metal components mainly in steel , in small and medium series, with various processes performed internally, using numerical and traditional control machines.

We can supply both small parts that are simply welded and finished products, complete with treatments, assembly, packaging and testing.

Via delle Moie, 15

25073 Bovezzo (BS)

P.IVA e C.F. 03167540982

Contacts

info@zanettiofficine.it

ammistrativo@zanettiofficine.it

ufficiotecnico@zanettiofficine.it

Pec: zanettiofficine@legalmail.it

Tel. 030/2711788 r.a.

Fax: 030/2713335

PRIVACY POLICY

Information on the processing of personal data, pursuant to art. 13 of the EU Reg. 2016/679.

The EU Regulation 27 April 2016, n. 679 provides for the right to the protection of personal data concerning natural persons. In compliance with this legislation, our company, which intends to process your personal data, wishes to inform you in advance, pursuant to art. 13 of EU Regulation 2016/679, that this treatment will be based on the principles of lawfulness, correctness and transparency, purpose limitation, data minimization, accuracy, conservation limitation, integrity, confidentiality and responsibility, as well as protection of your privacy and Your rights.

Therefore we provide the following information on the processing of your personal data that we intend to make.

The treatment has the purpose of being able to contact you, following your request, for:

- Provide the requested information, formulate estimates, manage pre-contractual and internal operational and management needs;

- & nbsp; Carrying out activities having commercial / promotional / information / news / purpose concerning products / services, events and initiatives related to them provided by Costruzioni Meccaniche Zanetti S.A.S. by mail and / or telephone and also through automated systems (SMS, e-mail, e-mail marketing / newsletter).

- & nbsp; entrusted parties who are part of our company;

- external parties that carry out management of information systems and website on behalf of our company;

- subjects to whom the right to access the data is granted by law or regulation;

- other subjects provided for by law.

The treatment will be carried out by specially appointed parties, in the following ways: electronic and paper.

The provision of your data is obligatory for you for the purpose referred to in point A). We therefore invite you to omit data that is irrelevant in relation to the specific purposes for which it is provided. Any failure to provide your data could make it impossible to be able to contact you to provide information, including information on products / services and for internal operational or management needs.

The conferment of your data is optional for you for the operations referred to in point B).

The subjects in charge of personal data (personal and common data) can be communicated are the following:

The data collected for the purpose referred to in point A) will be duly kept for a maximum period of 10 years, pursuant to art. 2220 c.c. or, pursuant to art. 13. c.2, lett. a), second part of EU Reg. 2016/679, for a variable term, according to criteria of balancing legitimate corporate interests (related to tax inspections, any special correspondence, such as disputes, arrears, legal aspects, periodic purchase, statistical purposes, productive, quality).

The data collected for the purposes referred to in point B) will be duly preserved in compliance with the regulations in force for a period of time not exceeding that necessary for the purposes for which they were collected and processed.

It is not possible to disseminate the data (dissemination = communication to undetermined subjects).

The Data Controller is Costruzioni Meccaniche Zanetti S.A.S. with headquarters in Via delle Moie, 15 25073 Bovezzo (BS) e-mail info@zanettiofficine.it.

According to the art. 13, par. 2, lett. b), c), d) of the EU Regulation 2016/679, by contacting the Data Controller, you can assert the following rights, relating to the processing of personal data: • right to access (art. 15);

• right of rectification (art. 16);

• right of cancellation (art. 17);

• right of limitation (art. 18);

• right to data portability (art. 20 );

• right of opposition (art. 21);

• right to lodge a complaint with a supervisory authority (art. 77);

• right to withdraw consent, in the cases provided for by the art. 6, par. 1, lett. a) or by art. 9, par. 2, lett. a).

This document is updated to 09/30/2018.